responsible development

getting results the right way

Safety is embedded in everything we do at Chevron Canada. We strive to make sure everyone on our sites goes home safe every day. Our safety culture is based on two underlying principles: do it safely or not at all; and there is always time to do it right.

Responsibly developing Canada’s onshore and offshore energy resources means improving our environmental performance and reducing the potential impacts of our operations.

our culture of operational excellence

Our Operational Excellence Management System puts into action our Chevron Way value of protecting people and the environment, systemically managing workforce safety and health, process safety, reliability and integrity, environment, efficiency, security, and stakeholders.

Getting results the right way makes us who we are, and we apply the Operational Excellence Management System to improve safety in our operations, workforce and communities:

eliminate fatalities, serious injuries and illness

eliminate high-consequence process safety incidents and operate with industry-leading reliability

assess and manage significant environment risks

use energy and resources efficiently

prevent high-consequence security and cybersecurity incidents

address risks through stakeholder engagement and issues management

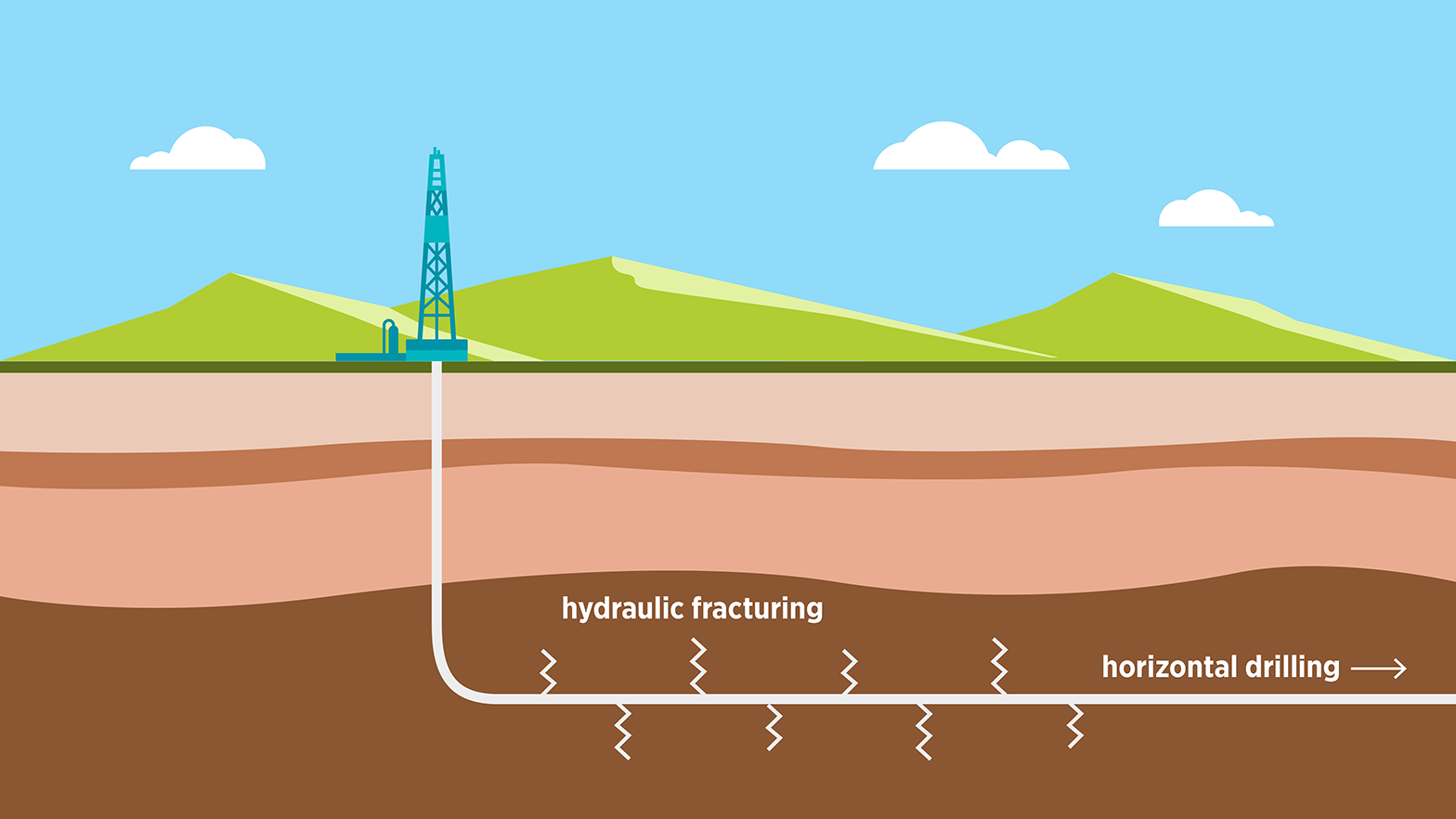

hydraulic fracturing

unlocking oil and gas through safe and proven hydraulic fracturing technology

Production of shale gas often requires formation stimulation to help produce the hydrocarbons. Hydraulic fracturing is a well completion technique that pumps a fluid-sand mixture into a formation under high pressure, stimulating the formation to extract oil and natural gas from the deep underground rock. Through continued innovation and responsible operations, Canada is safely leading the way to help meet the world’s growing energy demand using this technology.

how chevron protects the environment during hydraulic fracturing

At Chevron Canada, we believe that protecting the environment can go hand in hand with meeting the world's energy needs by minimizing our impact from operations.

- Our hydraulic fracturing operations are more than one kilometer below any potable groundwater sources.

- Our wells have multiple layers of steel casing and cement, forming a continuous barrier between the well and the surrounding formations, including potable and non-potable aquifers.

- During drilling and completions operations, wells are monitored by on-site teams to ensure immediate response to operating conditions.

- We regularly test to verify long-term integrity throughout the life of all wells.

- We dispose all flowback water at designated facilities in accordance with all government regulations.

- We adhere to provincial regulations and industry best practices. Chevron Canada is a member of the Canadian Association of Petroleum Producers (CAPP) and abides by its guiding principles for hydraulic fracturing.

induced seismicity

minimizing risk of induced seismicity by meeting and exceeding regulations and best practices

Induced seismicity is seismicity caused by human activity. It has been associated with several industrial practices such as dam building, mining and hydraulic fracturing. The energy released by hydraulic fracturing or injections into wells can trigger movement along existing fault lines, leading to induced seismic events. In Alberta, energy companies must follow strict regulations aimed at reducing the risk of induced seismicity related to their operations.

Chevron Canada complies with all government regulations and meets or exceeds industry best practices to manage induced seismicity.

- We perform subsurface studies to address the seismic risks associated with operations. This includes geo-mechanical modeling and design of fracturing treatments to ensure the fracture growth is confined to our target zone.

- We complete a detailed risk assessment and submit a response plan to the regulator for use if a seismic event were to occur.

- We use seismic monitoring equipment to monitor for induced seismicity during hydraulic fracturing operations.

- In Alberta, we follow the Alberta Energy Regulator’s traffic light system to mitigate risks. This is a specific seismic protocol in the Fox Creek area based on geology and surface structures that limits the impact and potential of induced earthquakes from hydraulic fracturing.

- When conducting hydraulic fracturing operations in proximity to populated areas, we install an enhanced monitoring array and follow a traffic light protocol that is an order of magnitude more sensitive than required by the Alberta Energy Regulator.

- We work closely with other operators in the Fox Creek region to share information related to induced seismicity to assist the industry in operating more safely.

you might also be interested in

what is hydraulic fracturing and is it bad? opens in new window